Die cut stickers are by far the most popular sticker option. If you are researching custom stickers, you are bound to stumble over the term.

But what exactly does it mean? What is a custom die cut sticker? And what makes it special? Are you confused?

We’re here to help you. This short guide tells you exactly what a die-cut sticker really is – jargon-free and easy to understand.

Don’t have time to read? Then watch the short video below or read on to find out more.

The term ‘die cut’ describes how your sticker is cut. It tells you just as much about the shape of your sticker as terms like "rounded corners" or "square" would.

It means your sticker is cut in a custom shape, usually around your design. The term goes back to the old days when this type of sticker was cut with heavy metal dies.

Since then, technology has changed, but the name has stuck (pun intended). A better name for them would be custom-shaped stickers.

If you buy a custom die cut sticker today, it will be digitally cut around the edge of your design, through the vinyl and paper backing, like this:

Important!

The term die cut is not related to the material of your sticker. You can still choose your perfect material to make your sticker waterproof, durable, sparkly, or have a glossy or matte finish.

A great place to start is our materials page or you can take our quiz. We can die cut any material so browse the features of each and find your perfect match to create a great-looking sticker.

Why is it called die cut?

The term comes from an old cutting technique using pre-made metal ‘dies’. You can imagine a die to look like a cookie cutter.

Thin strips of sharp metal were formed into the desired shape to make a die in the exact shape. They are expensive and time-consuming to make. After all, each of them has to be made in custom shapes.

This custom die is then used to cut straight through your materials and create the desired shape. The die cutting process looked like this:

This is how custom-shaped stickers came to be known as die-cut stickers.

However, die-cutting is outdated. Most of the print industry is now using digitally controlled knives and high-speed lasers to cut custom stickers of all shapes and sizes to save time and money. This also enables us to cut delicate designs precisely and quickly.

For you, this means that you can include more than one custom shape in one order without breaking the bank. It also shortens lead times and limits the excess material, lowering the cost of your sticker.

Just look at this example of laser cutting stickers at 50 meters per minute!

Pretty cool, eh?

Die cut stickers vs kiss cut stickers

The main difference between die cut stickers and kiss cut stickers is the way they are cut.

Die cut stickers are individually cut through the sticker mater and the backing paper. Kiss cut stickers are only cut through the material layer. The paper backing stays intact and leaves an extra border around your stickers.

It can sound a little complicated, but this GIF helps to explain the difference:

Recommended reading: Kiss cut stickers vs die cut stickers.

Die cut sticker FAQs

Since die cut stickers are so highly customisable, it can be quite difficult to answer all questions in a single article. So let's troubleshoot some of the questions we are often asked.

Are die cut stickers waterproof?

If a sticker is die-cut, it doesn't mean it's waterproof. Die-cutting refers to how a sticker is cut, not the material.

Plastic-based materials tend to be waterproof, whereas paper stickers are not. Our waterproof sticker range includes all vinyl stickers, ranging from our most popular white vinyl option to our premium vinyl materials with effects.

This is an essential aspect to get right as the durability of your material determines how you can use your die cut stickers.

Are die cut stickers reusable?

No, we do not recommend reusing our die cut stickers. As you remove them from the surface you originally stuck them to, the adhesive becomes less sticky.

This means that we cannot guarantee that your custom stickers will perform similarly well when reapplied.

Once you peel them from the paper backing, your custom cut stickers should be applied immediately to avoid contamination of the adhesive.

Every dirt or dust particle caught under the adhesive film can interfere with the adhesion of your stickers and creates unnecessary air bubbles.

What size are die cut stickers?

The benefit of going custom is that you can choose your perfect size. This will, of course, depend on the way you intend to use your stickers.

However, we have observed a go-to size range that works for many purposes over the years. Here are some recommended sizes for our most popular applications:

How thick are die cut stickers?

When it comes to stickers, we associate thickness with quality. The thicker the stickers, the more premium they feel - and the easier they are to peel.

Since die cuts can be printed on a whole host of materials, the thickness of your custom stickers ranges from around 245 microns to 280 microns. That is about 0.245 to 0.28 mm.

Die cut sticker printing uses microns and GSM (grams per square metre) as units, simply because stickers are comparatively small.

If you are looking for more details on your options, check out the datasheets attached to each of them on our materials page.

How much do die cut stickers cost?

The price of die cut stickers changes depending on the material, the size and the quantity you choose.

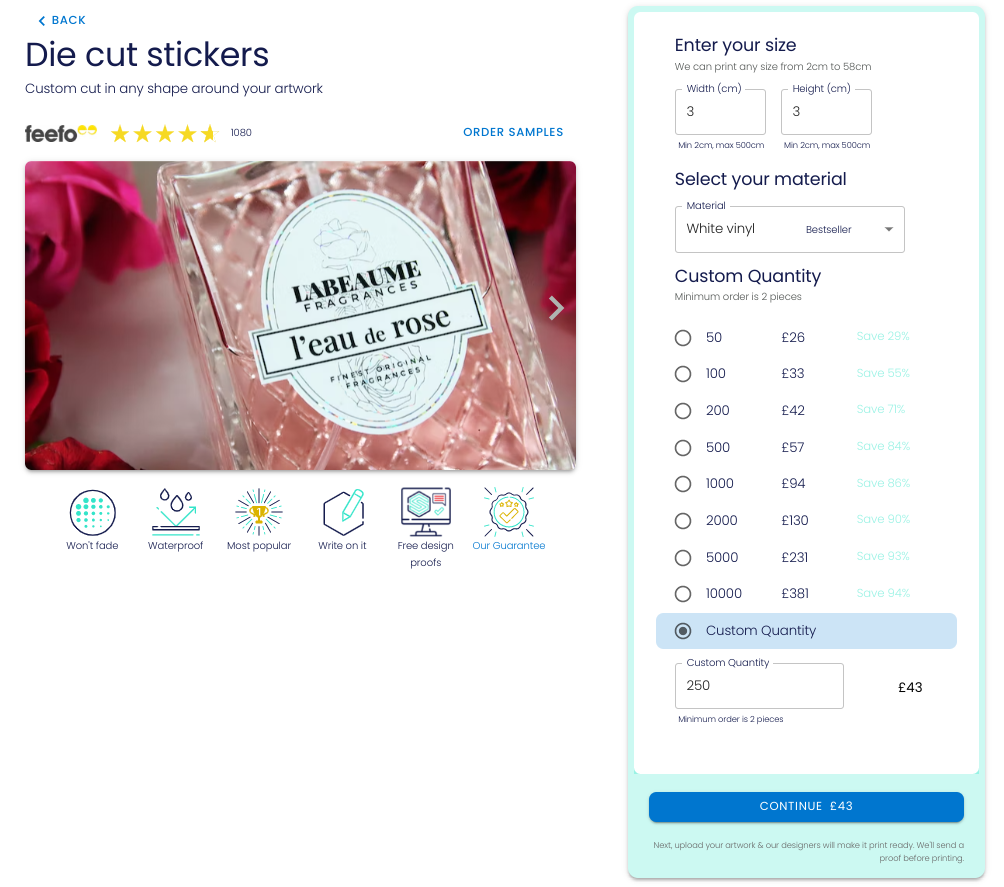

Since we offer custom stickers that are manufactured to fit your needs, we do not have a set pricing list. Instead, we work with a live pricing calculator on every product page.

You can enter your custom size, material, and desired quantity, and it will automatically generate your price - bulk discounts included. The great thing about that is that you can play around with the quantities and sizes until you are 100% happy with the price.

Let's look at an example.

What is the cost of 250 die cut stickers at 3x3cm?

250 die cut stickers at 3x3cm printed on our bestselling white vinyl material cost £43 (or 17p each). The custom shape will not increase the cost of your stickers.

Our pricing calculator will give you an overview of the pricing breakdown at different sticker quantities. It also allows you to enter a custom quantity at the bottom, so you can create an instant custom quote.

If you'd rather make your own, have a look at how to make die cut stickers.

Want some die-cut stickers?

If you would like to get some die-cut stickers to see precisely what all the hype is about, how easily they peel and the cutting quality in detail, for £9 you can get 10 die cut sticker samples with your design printed on.

Looking for inspiration? Then check out the best die cut stickers.

If you have any questions or want to tell us about how you use die cut stickers, please get in touch with us.